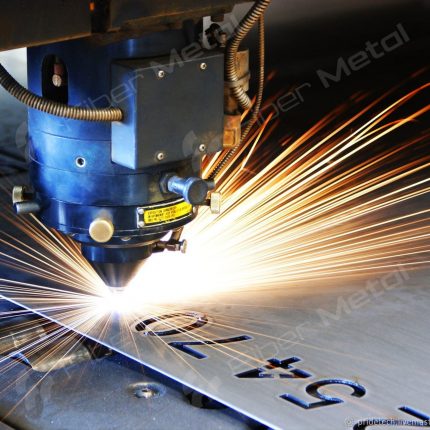

Laser Cutting

We perform cutting operations for a wide variety of materials using laser cutting services. We use laser cutting machines to precisely cut or shape materials. Laser cutting, a modern technological service, is used to cut many materials such as metal, sheet, wood, plastic, aluminum, steel, and stainless steel. Offering high precision and fast production, laser cutting is used in various fields, from industrial production to personal projects. For laser cutting services that provide significant advantages across various industries, you can contact our company, Fiber Metal.

What is Laser Cutting?

Laser cutting is a method preferred for cutting materials such as iron, aluminum, bimetal, and stainless steel. It is commonly used for industrial production. Additionally, laser cutting has become a technology increasingly adopted by schools, SMEs, and hobbyists.

Laser cutting is generally achieved using optical tools to direct high-powered laser beams. Laser optics and CNC are used to guide the material or laser beam and serve their specific purposes.

A commercial laser used for material cutting includes a motion control system to follow the CNC or G-code for the cutting pattern.

The focused laser beam is directed onto the material. After this, the material is melted, burned, vaporized, or blown away with a gas jet. The result is a high-quality surface finish with a clean edge. Industrial laser cutters are ideal for cutting flat sheet materials, but laser cutting is also used for cutting profiles and pipe materials. There are various laser cutting methods available for cutting metals.

Laser Cutting Prices

Laser cutting is a widely used method in material processing and manufacturing, characterized by its advanced technology. It is used for cutting, drilling, or shaping various materials and plays a significant role in industrial production. Laser cutting prices vary based on several factors. These include the type of material, its thickness, the size of the cut, and the complexity of the cut. Prices also differ based on the specific laser technology used and the order requirements. For information on laser cutting prices and to take advantage of our services at the most competitive rates, please contact us.

Laser Cutting Process

High-density laser beams are used for cutting various materials. The laser cutting process involves several steps using the laser beam produced by the machine. Laser cutting, which ensures clean and precise cuts, starts with preparation and setting the laser according to the type of material. The material is cut using the adjusted laser beam’s power and cutting speed. After cutting, final checks, cleaning, and additional procedures, if needed, complete the laser cutting process.