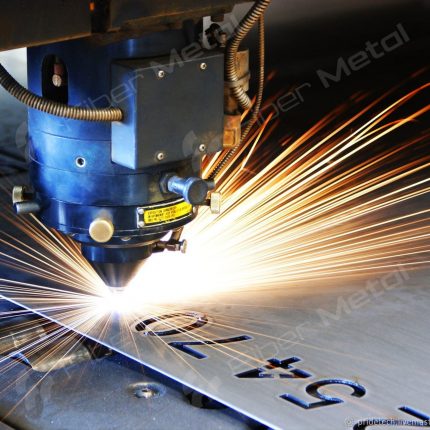

Metal Laser Cutting

Laser cutting is a method of concentrating high energy into a small area with a focused light beam. During the metal laser cutting process, the metal that comes into contact with the laser beam burns, melts, or vaporizes, thus achieving the cutting or drilling operation. Metal laser cutting is an evolving industry that involves cutting metals using this method.

Metal laser cutting is used for materials of various thicknesses. At the core of this method is a laser beam that is directed, shaped, and focused. The laser beam heats the metal material to its melting or vaporization point by focusing on it.

In short, each material has its own limitations and characteristics in metal laser cutting. It is a misconception to think that the laser beam can easily cut all materials since not all materials are suitable for laser cutting. The cutting process of different materials requires specific energy levels. Therefore, our Fiber Metal company uses the appropriate machine based on the thickness of the metal sheet to be processed.

Metal Laser Cutting Prices

Metal laser cutting is among the widely used production methods in many areas of the industrial sector. A high-energy laser beam is used to cut metal sheets or similar plates into specific shapes. The prices of metal laser cutting vary due to several factors. One of the main factors influencing metal laser cutting prices is the type of material to be cut. The thickness of the metal sheets or plates affects the power of the laser used for cutting, and thus the quality of the material influences the price. The complexity of the shape to be cut, the cutting time, and the workload are also critical in determining metal laser cutting prices, as they affect the difficulty and quantity of the cutting process.

Since metal laser cutting prices depend on the project’s specifications, requirements, and quantity, please contact our Fiber Metal company for a precise price quote.

How is Metal Laser Cutting Done?

Metal laser cutting is performed by our Fiber Metal company using different methods and metal laser cutting machines. The process is carried out by metal laser cutting machines, where a focused laser beam first heats and then melts the metal locally. With metal laser cutting, which ensures clean and precise cuts, metal sheets are cut into the desired shapes and patterns. For the most competitive laser cutting prices and to have metal laser cutting done, please contact our Fiber Metal company.